Your Guide to Expanded Metal Sizing

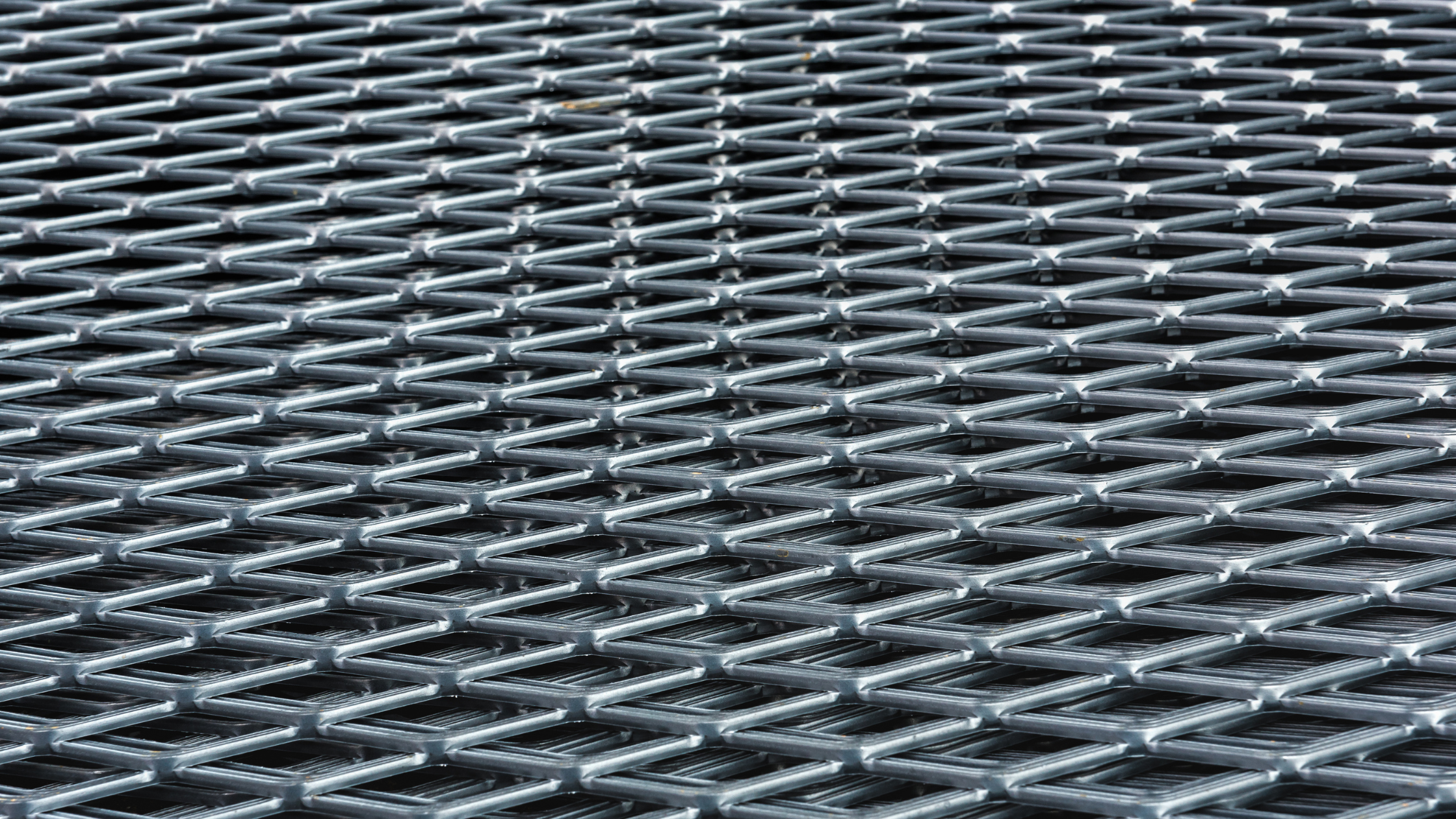

Stainless steel expanded metal grating is commonly used for flooring, shelving, security screens, and barriers. Expanded metal grating is also considered one of the most economical materials for industrial, architectural, and commercial applications.

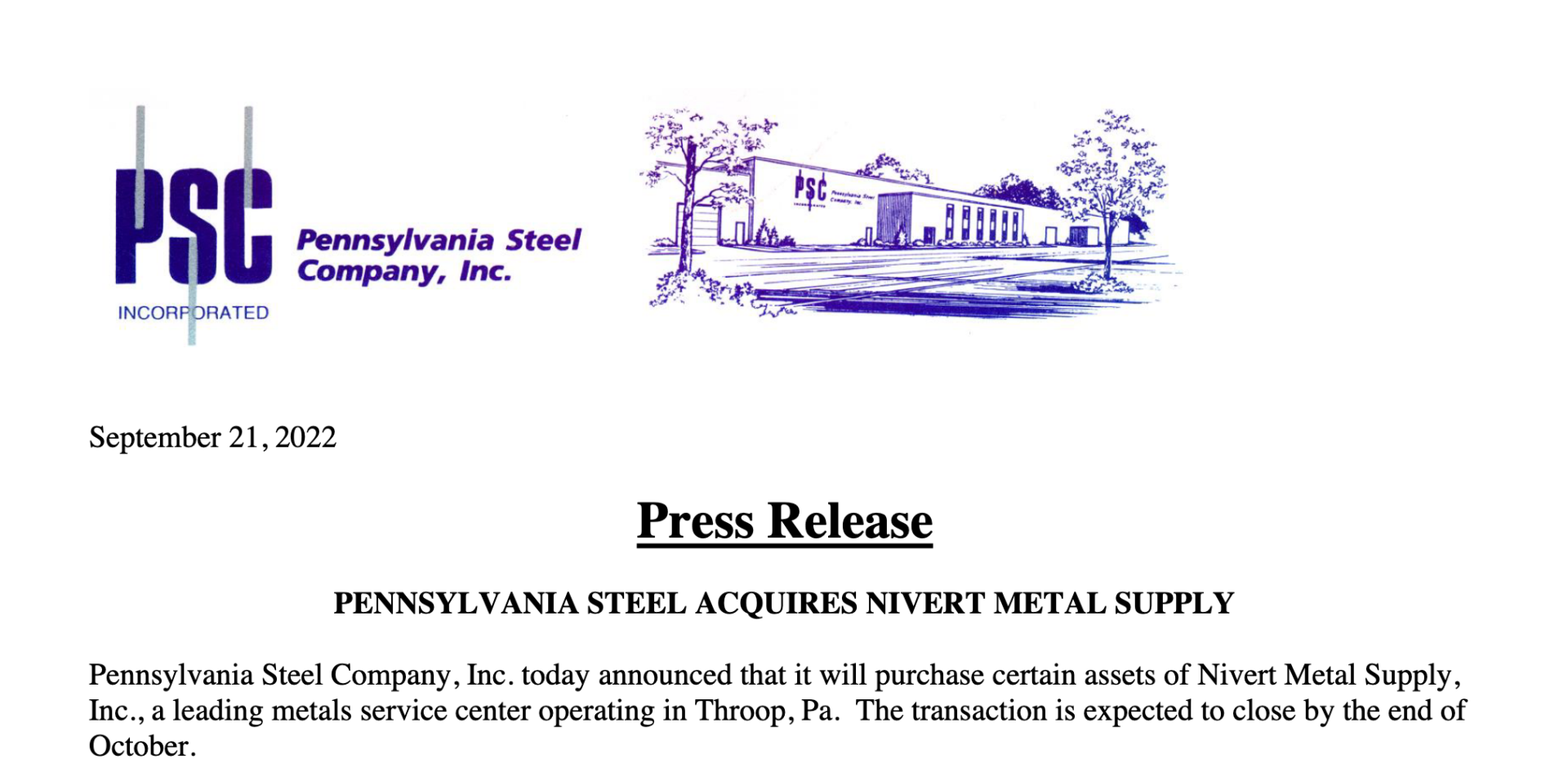

Pennsylvania Steel Co. offers a variety of stainless steel expanded metal and grating products. We can walk you through our expanded metal sizes and help you quickly and easily identify your project’s ideal expanded metal sizing.

What Are the Types of Expanded Metal?

Common types of expanded metal include:

1. Standard

Available in many gauges and open sizes, standard expanded metal features strands and bonds set at the same angle. This boosts the metal’s power and rigidity. At the same time, it improves the metal’s airflow.

2. Flattened

Flattened expanded metal is produced through cold rolling. It’s a great option if you want a smooth surface.

3. Hexagonal

Air, light, fire, sound, and liquid can seamlessly move through hexagonal expanded metal. At the same time, the hexagonal shape strengthens the metal.

4. Architectural

Architectural expanded metal features a diamond design with distinct aesthetic elements. For a terrific mix of style and function, go with architectural expanded metal.

5. Micro

This consists of a light gauge metal with small holes. It can also have flattened, regular, hexagonal, or square openings.

How to Measure Expanded Metal

To measure expanded metal, you first need to consider whether the metal is raised or flattened.

In its original form, expanded metal has a raised appearance in which angular strands incline from the plane of the sheet. You’ll want to account for the following measurements:

- Longway Pitch: Horizontal measurement from center to center based on the size of the tool used during production

- Shortway Pitch: Vertical measurement from center to center based on the expansion that occurs during production

- Strand Width: Measurement of the width of the angular strand that forms during production

- Strand Thickness: Measurement of expanded metal thickness

With flattened expanded metal, measure the longway and shortway aperture in addition to strand width and thickness. Longway aperture refers to the horizontal measurement from one internal aperture point to another. Shortway aperture is the vertical measurement from one internal aperture point to another.

What Do Expanded Metal Numbers Mean?

Expanded metal numbers denote the metal’s dimension and gauge. The first number indicates the metal’s nominal dimension or short way of design (SWOD), and the second number typically indicates the metal’s gauge or weight per 100 square feet.

How Do You Read Expanded Metal Sizes?

An expanded metal size chart is generally used to read expanded metal sizes. This chart includes the following columns:

- Style: Based on a measurement of the edge of the expanded metal to the straight edge and may include a letter at the beginning to denote the material (for example: “A” for aluminum)

- Weight: Measured in pounds per square foot

- Opening Size (in inches): Denotes the metal’s SWOD and long way of design (the diagonal length of the long diamond)

- Strand Size (in inches): Indicates the strand’s width and thickness

- Approximate Open Area %: Represents the approximate area of an irregular region surrounded by curves

If you have more questions about expanded metal dimensions, the experienced team at PA Steel is happy to help.

Pennsylvania Steel Company Is Here for Your Metal Needs

We own and operate regional steel warehouses in Bensalem, Whitehall, and York, Pennsylvania, along with Richmond, Charlotte, New England, Long Island, Cleveland and many other locations across the northeast. If you want expanded metal services, we’ve got you covered.

For more information about our expanded metal services or to request an expanded metal project quote, please get in touch with us today.