The vast differences between metal types make the variety you use for a project significant. For example, steel skyscraper construction metals require much more strength than the delicate metals used in producing jewelry.

How can fabricators accurately determine the appropriate steel type? Alloy steel and carbon steel possess specific properties and capabilities to function in different roles. Pennsylvania Steel Co. specializes in steel processing techniques and how to pick a suitable metal for the job. We provide top-quality metals for various East Coast locations with warehouses in Pennsylvania, New York, Connecticut, the Southeast, and Ohio. Below, we outline the significant characteristic differences between alloy steel and carbon steel.

What is Alloy Steel?

The phrase “alloy steel” is a blanket term to describe the resulting product from mixing metal elements. Common alloying elements include but are not limited to:

- Silicon

- Chromium

- Boron

- Nickel

- Aluminum

- Cobalt

- Tungsten

The addition of particular alloys affects the steel’s hardness, toughness, wear resistance, heat resistance, and tensile strength.

Types of Alloy Steel

Varying combinations of alloy metals result in different physical properties and characteristics. These combinations fall into one of two general categories:

- High-Alloy Steel: contains a high percentage of other alloying elements (most commonly: stainless steel, which is approximately 12% chromium)

- Low-Alloy Steel: contains a lower percentage (1%-5%) of alloying elements, making it generally less costly to use

Uses & Applications

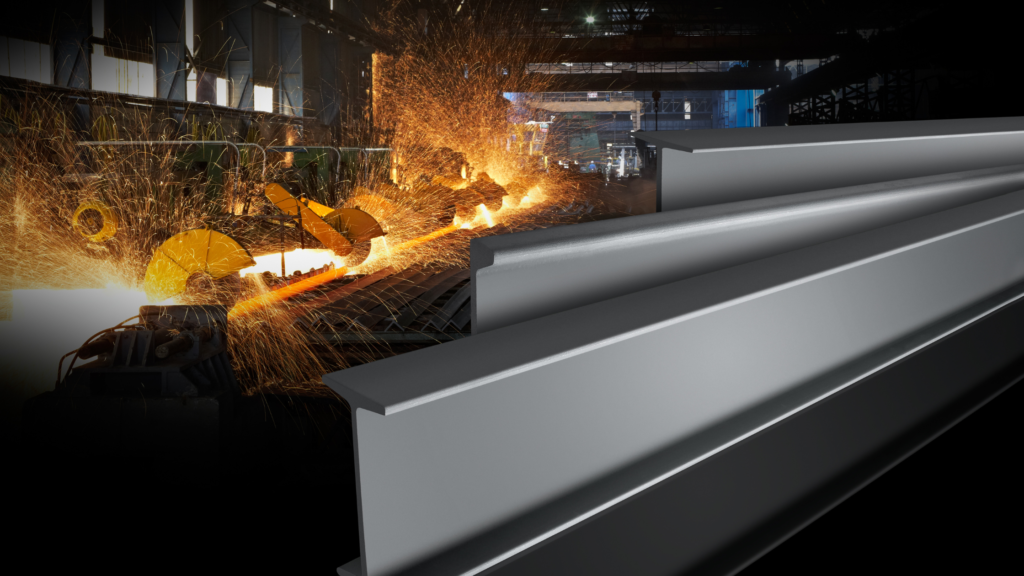

Metalworkers use alloy steel as a manufacturing material in assorted industries, including mining, aerospace, automotive, and railroads. Industrial demand for alloy steel is high, as you can customize its alloying features for diverse structural needs. Its machinability makes it a desirable material for transportation infrastructure and other construction purposes.

What is Carbon Steel?

Put simply, carbon steel is an alloy (mixture) of carbon and iron. The high amount of carbon (ranging from 0.25%-1.25%) in this type of steel makes it incredibly durable and versatile, depending on the specific percentage of carbon.

Types of Carbon Steel

Carbon steel is prevalent and diverse in its applications. In general, carbon steel falls into one of three categories:

- Low-Carbon Steel (>0.25%): the most widely-used variety of carbon steel that is particularly ductile and welds easily

- Medium-Carbon Steel (0.25%-0.6%): slightly stronger due to higher manganese concentration (0.6%-1.65%)

- High-Carbon Steel (0.6%-1.25%): high wear resistance and very low elasticity, with a manganese concentration ranging from 0.3%-0.9%

Typically, this type of steel becomes more challenging to work with as the carbon percentage increases. For this reason, high-carbon steel often has more specialized applications, including springs, wires, and knives.

Uses & Applications

Like alloy steel, carbon steel is useful in numerous industries, especially in the chemical, oil, and gas sectors. Carbon steel’s advanced, versatile strength makes it ideal for pipes, pressure vessels, cutting tools, and even weaponry.

Comparing Alloy Steel vs. Carbon Steel

Is carbon steel strong? Is alloy steel stronger than high-carbon steel? These answers depend on what you mean by “strong.” The list of attributes below expands on specific comparisons between steel types, including overall strength.

Chemical Composition

As previously mentioned, carbon steel contains mainly two elements: carbon and iron. Any other present alloys are usually regarded as impurities. On the other hand, alloying of additional components (manganese, nickel, chromium, etc.) in alloy steel alters the chemical properties and limits of the resulting metal.

Strength

Overall, fabricators regard carbon steel as having higher strength than alloy steel. In other words, carbon steel can withstand significant pressure but doesn’t bend easily. Alloying metal variations adjust tensile strength.

Hardness

Carbon steel owes its superior strength to being harder than alloy steel. However, higher carbon content decreases ductility and weldability, making this steel type slightly more challenging to work with.

Melting Point

In general, alloy steel’s additional elements give it a higher melting point than carbon steel.

Malleability

Steel becomes less malleable as you add more alloying metals. Therefore, the lack of variation in carbon steel’s composition allows for better malleability than steel alloys.

Weldability

Alloy steel is difficult to weld and prone to cracking, giving carbon steel higher weldability. However, the prior allows for adjustment of certain alloying elements to help streamline heat treatment.

Corrosion Resistance

Alloy steels have higher corrosion resistance than carbon steel, meaning they deteriorate (rust) at a slower rate.

Cost

The price of carbon steel varies and depends on the metal’s carbon content. As the carbon percentage increases, so does the price. Additionally, alloy steel is often costly due to varying amounts of alloying elements.

Quality Alloy and Carbon Steel from Pennsylvania Steel Co.

Only premium metal materials can craft superior construction projects. The experts at Pennsylvania Steel proudly supply leading manufacturers in numerous sectors throughout the U.S., from Charlotte, NC to our Cleveland steel warehouses. If you need alloy or carbon steel for your next project, request a quote from the Pennsylvania Steel Company Inc. team today.