How to Choose the Right Grade of Tool Steel

Using tool steel in manufacturing or construction is a common practice, but tool steels are not all the same. With various tool steel grades available, choosing the correct one can either make or break your production process.

Understanding each type of tool steel is pivotal for any project. Performance over price. Machinability over toughness. Safety over everything else. Looking at the various uses and adaptations to specific applications also helps.

Choosing the right grade of tool steel can be tricky without the right knowledge. It requires learning about its properties to select the appropriate grade. Luckily, the pros at Pennsylvania Steel have created this how-to guide to make your next discussion with tool steel distributors easier.

Identifying the Types of Tool Steel Used

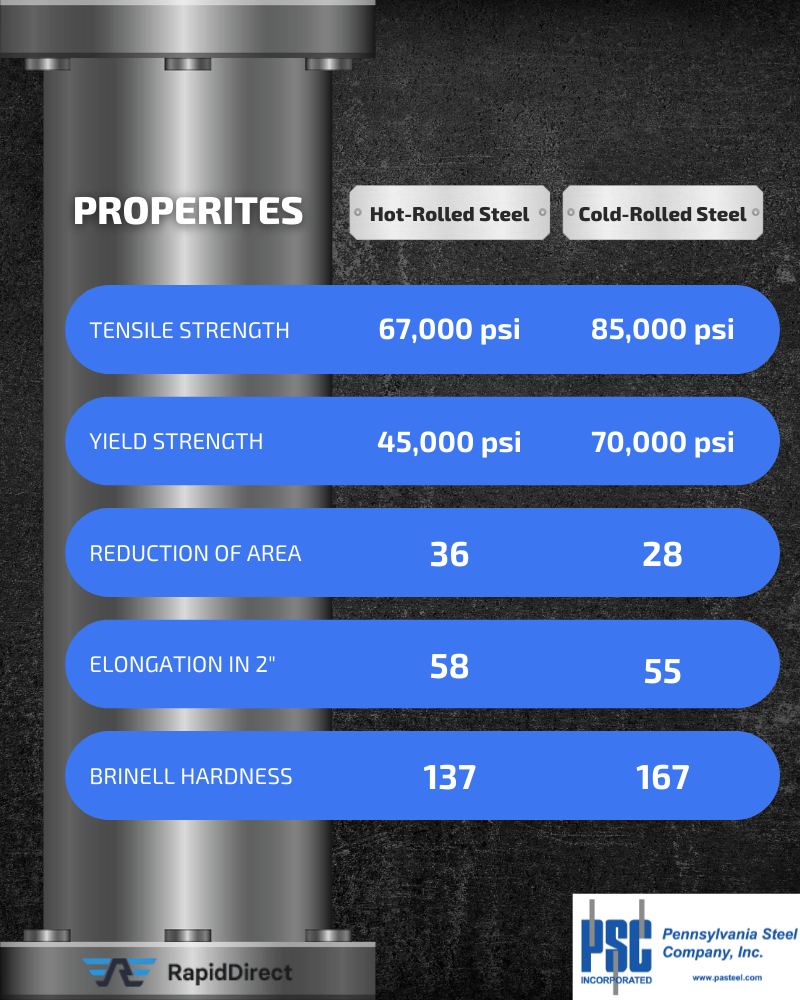

Often, projects choose tool steel based on specific mechanical properties, such as:

- Abrasion resistance

- Tensile strength

- Wear resistance

The range of tool steel grades includes types optimized for different uses—cutting, pressing, or molding materials.

Determining its usage is the first step in selecting the right grade of tool steel. Let’s review the different types of tool steel available.

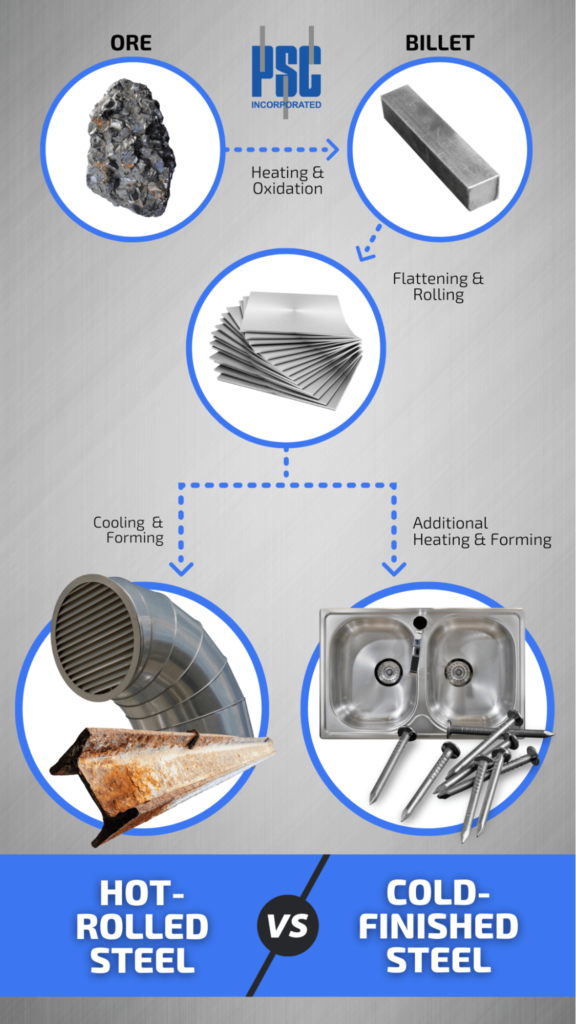

- Cold-work tool steel: Commonly used for applications involving shaping materials at or near room temperature. These steels resist wear and high abrasions excellently. Ideal for manufacturing dies, cutting blades, and stamping tools. Common grades are A, D, and O.

- Hot-work tool steel: Designed to withstand elevated temperatures and thermal cycling. Regularly used in die casting and hot gorging. H13 is one of the popular grades. It offers a balance between toughness and thermal fatigue resistance.

- Water-hardened tool steel: Economical and suitable for applications requiring mid-level wear resistance and hardness. Typically used in frequently-sharpened tools (chisels, cutters), but not suitable for high temperatures. Known as W-grade steels, they harden upon quenching in water.

- High-speed tool steel: Common for cutting operations like drilling, milling, and turning. They stay hard and can cut even at elevated temperatures. Grades include HSS, M, and T.

- Shock-resistant tool steel: Made for high-impact applications (chisels, hammers), designed to absorb shock without chipping. Grades S1, S5, and S7 are common.

- Plastic mold: Specially formulated for machining and polishing to make molds for plastics. It has good machinability, but is unsuitable for high temperatures. It’s also known as P-grade steel.

- Special purpose: These are unique alloys tailored for specific applications or properties. Generally, it consists of two grades, L and F. L-grade steels are magnetic and often used in dies. Meanwhile, many usually use F-grade steels for unique properties like ease of machining.

Selecting the Right Tool Steel Grade

How do you maximize performance and longevity in the applications of tool steel? Choose the right grade. The tool steel grades define their properties and intended uses. Then, there are factors influencing the correct grade to choose.

Durability in Different Environments

Consider the tool steel’s durability in different conditions—abrasion, corrosion, and general wear. Then, consider the working environment and temperature where you will process the steel. Anticipate things like plastic deformation potential. This will ensure your chosen grade offers the needed stability and tool life.

Chemical Compositions

The tool steel’s chemical composition may also influence your selection. Factors like carbon content and alloying elements (e.g., chromium) influence its mechanical properties, which in turn contribute to its durability and longevity.

Performance Requirements

Determining what’s required of the tool steel you’ll be working with is crucial. For example, some tool steels are more difficult to machine than others. A2 or O1 grades are easier to machine, while tougher ones like D2 may need carbide tooling. Before you choose, figure out how and what you are going to use them for.

Certification and Standards

This is not a necessity. However, checking the certification and standards of tool steel grades contributes to safety. Certifications ensure the material meets the industry benchmarks for critical properties like chemical composition and hardness.

ASTM or ISO have standards for the proper classification of tool steel grades. This will help maintain quality and performance across different batches of tool steel.

Cost and Availability

Cost and availability matter. More common grades are likely cheaper and more readily available. They’re preferable for large-scale or frequent operations. Yet, specialized tool steels may be more expensive and less accessible. Your budget, in the end, will balance all the aspects you need to consider in selecting the right grade.

Supplier Selection

This relates to availability. Evaluate your supplier’s performance when choosing the right tool steel grade. Trustworthy distributors, like Pennsylvania Steel, offer a wide range of tool steels. They increase the chance of finding a material fitting your project’s specific needs. They will also meet certification and standard requirements. Moreover, reliable tool steel distributors can offer quality assurance and suitability for various applications.

Get the Right Tool Steel Advice from PA Steel

The primary use of tool steel will influence your selection of the right tool steel grade. The following factors you must consider are chemical compositions, durability, performance requirements, and certifications and standards. Finally, your budget and availability will be the deciding factor.

PA Steel is available in many locations throughout the Eastern US. We offer metal products just as comprehensively as any Ohio steel company. Need help choosing the right tool steel grade? Turn to us! Visit PA Steel and get a quote for your tool steel.